Transactional and service-based organizations have widely adopted Lean Six Sigma as a valuable methodology for process improvement. These organizations see results using the DMAIC (Define, Measure, Analyze, Improve, and Control) methodology and tools such as project charters, process mapping, CTQs, and graphical and statistical analysis tools. Measuring performance with Sigma and DPMO (Defects Per Million Opportunities), however, can be overlooked by those outside of manufacturing.

What is Sigma?

Sigma is a measurement scale that compares the output (variation) of a process to the customer requirements defined in CTQ (Critical to Quality) metrics. Sigma shows how capable a process is of meeting CTQs by indicating how much of the data falls within the customer requirements. The higher the process Sigma, the more the process outputs, products, and services meet customer requirements—and the fewer the defects.

Is 6 Sigma the Goal?

Not necessarily. For manufacturers of life-saving prescription drugs or rocket ships to transport people to space, the answer is yes. With performance at 6 Sigma—or 99.99966%—the process is at close to flaw-free as it can get, with just 3.4 DPMO. Achieving this level of near perfection in all processes, however, may not be necessary or financially possible. A 3.5 Sigma—which indicates meeting customer expectations 97.7% of the time—is realistic for most service-related organizations. A coffee shop, for example, can afford a 2.3% defect rate because replacing a few cups of coffee here and there is easy and inexpensive compared to the amount of time and staff that might be involved in achieving 99.99% perfection. Prior to undergoing performance improvement processes, most organizations measure around 1 or 2 Sigma. This equates to meeting customer requirements only 30.9% to 69.1% of the time.

- With performance at 2 Sigma: 69.146% of products and/or services meet customer requirements with 308,538 defects per million opportunities.

- With performance at 4 Sigma: 99.379% of products and/or services meet customer requirements—but there are still 6,210 defects per million opportunities.

Granted, organizations operating with the volume of defects indicated by 2 Sigma or 4 Sigma are not generally involved in life-or-death processes. Yet, if a bank loan process fails to meet customer requirements less than 70% of the time, it is impacting customers’ lives—and the bank’s reputation and bottom line.

Making the Case for Using Sigma in Service Organizations

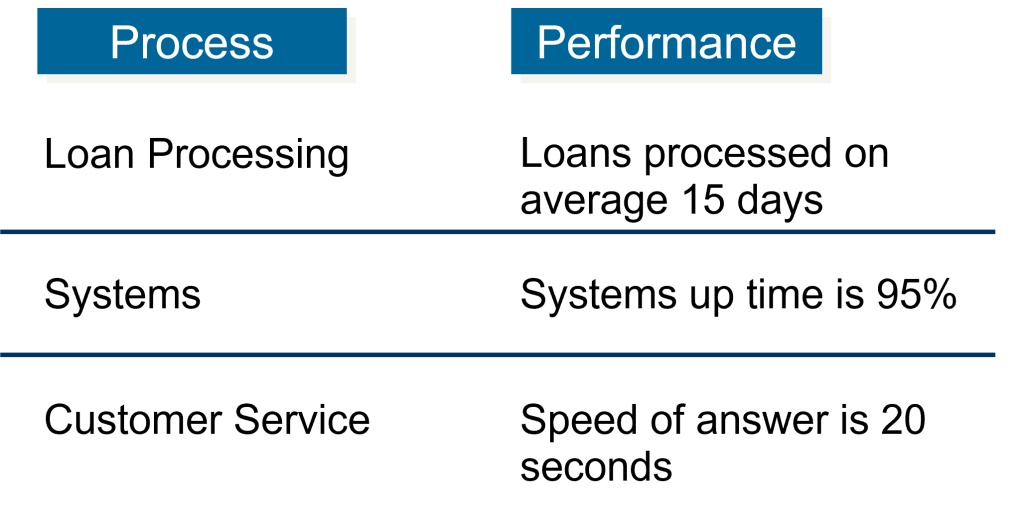

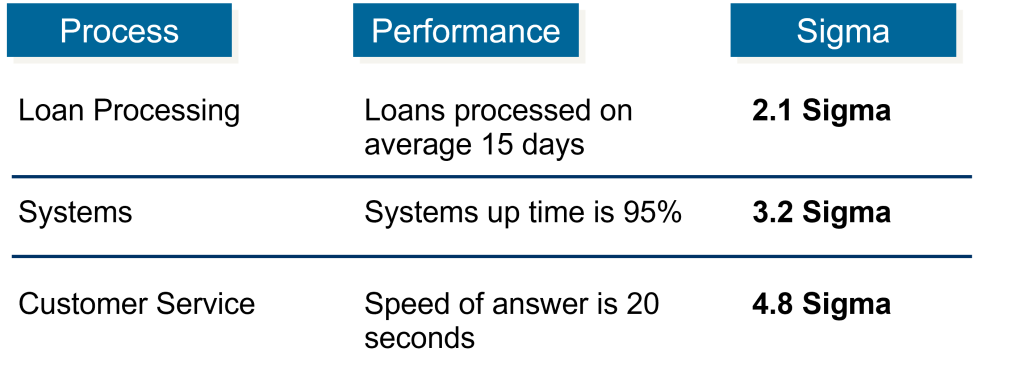

The great thing about Sigma is that it provides a common metric for measuring the performance of various processes compared to customer requirements. This makes it easy to not only spot the lowest performing processes but also to determine how much that process matters to the customer. A key to the success of a Lean Six Sigma improvement project is ensuring that the projects selected are meaningful and produce significant benefit to the organization. But when looking at current process performance measurements, how do you know which process to prioritize? The reality is that it is difficult to compare processes with very different kinds of measures.

Using Sigma—a common metric based on customer requirements—we can truly evaluate and compare process performance to determine which process is most in need of improvement.

In this example, Loan Processing is clearly where to start the improvement efforts. The Sigma indicates that nearly a third of our customers are not receiving their loans within the desired CTQ. From here, the Lean Six Sigma DMAIC methodology provides all the tools needed to get at the root cause of the problem, brainstorm solutions, and implement lasting change.

Get a Lean Six Sigma Refresher

Along with Acuity Institute’s full suite of Lean Six Sigma Belt Certifications, we are now offering Lean Six Sigma Green Belt Refresher and Lean Six Sigma Black Belt Refresher courses. If it’s been a while since you ran a project, this course is for you. The refresher courses are designed to reacquaint previously certified Lean Six Sigma Green or Black Belts with the essential tools used when leading Lean Six Sigma DMAIC projects. This comprehensive program includes 6 months of online access to 30 microlearnings focused on the key DMAIC deliverable and concepts as well as a project simulation. In addition, students receive a copy of Acuity Institute’s Lean Six Sigma toolkit and a full version of Acuity Institute’s Lean Six Sigma Black or Green Belt Course eBook. And if you would like to update your certification, you can opt to include the recertification exam. Lean Six Sigma certification is a prerequisite required to enroll.

Visit our website today to learn more about the Lean Six Sigma Green Belt Refresher and Lean Six Sigma Black Belt Refresher courses.