Lean Process Analysis is an essential tool for rooting out waste in Lean Six Sigma, Lean, and Kaizen events and process improvement projects. Whether you work in manufacturing or service, this tool is applicable because waste can be found everywhere, in any process. No industry, organization, or business is immune from waste.

Lean Process Analysis is a valuable tool for identifying process disconnects such as:

- Process gaps

- Redundant work

- Implicit or unclear requirements

- Tricky handoffs

- Conflicting objectives

- Common problem areas

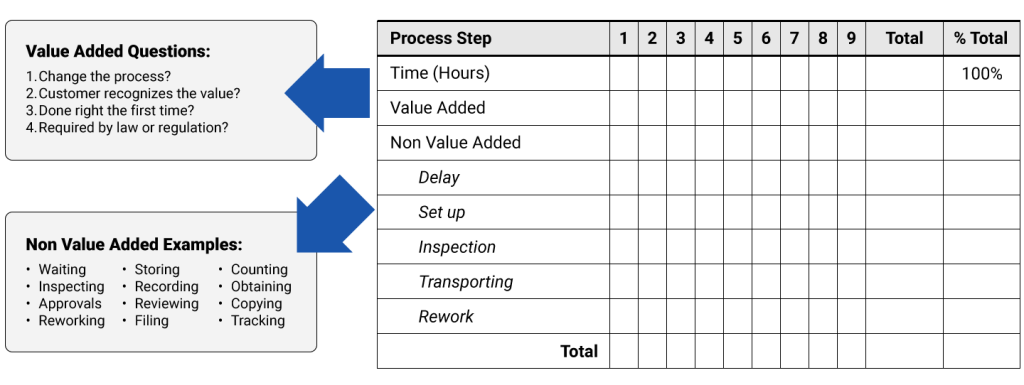

To get started with Lean Process Analysis, log every process step and develop an As-Is Process Map. Once the process steps are logged, the team can:

- Log the time each process step takes to complete.

- Determine the value of each process step and categorize it as Value Added or Non Value Added.

- Document the type of waste both in the Lean Process Analysis and the As-Is Process Map.

Linking the Cycle Time (total time for all process steps in hours or minutes) with the Lean Process Analysis helps develop a complete picture of the need for change and where this change should occur.

A Closer Look at Value Added and Non Value Added

Activities are Value Added when:

- The activity changes or transforms the product or service in some way.

- The activity is done right the first time.

- Customers are willing to pay for the activity.*

*When customers are willing to pay for an activity, it’s known as Customer Value Added (for example, quicker delivery times). If the customer is not willing to pay for it but the business is, this is Business Value Added (for example, regulatory activity).

Activities are Non Value Added when:

- The customer is not willing to pay for the activity, and the activity is not required for any other reason.

- The activity absorbs resources but creates no value (the direct translation of “Muda,” the Japanese term for waste).

- The activity uses resources over and above what is actually required to produce the product or service as defined by the customer.

As you can imagine, process owners and other key stakeholders may push back on what you deem Non Value Added in a process. To help others better understand what makes an activity Non Value Added, look to the categories of waste defined by improvement methodologies. Lean Six Sigma spells out five categories of waste: Delay, Set-Up, Inspection, Transporting, and Rework (DSITR). Lean uses the 8 Waste model defined by the acronym TIM WOODS: Transportation, Inventory, Motion, Waiting, Over-Production, Over-Process, Defects/Rework, and Skills. Whether you use DSITR or 8 Waste, categorizing the waste is useful because it helps the project team identify problems, describe problems with common language, and focus attention on solutions.